Quick Parts - Leading the Way in Laser Metal 3D Printing Technology

Introduction

Greetings! Welcome to Quick Parts, the leading provider of cutting-edge laser metal 3D printing solutions in the industry. As a highly proficient SEO and high-end copywriter, I am excited to discuss the fascinating world of laser metal 3D printing and how it is revolutionizing various sectors.

The Power of Laser Metal 3D Printing

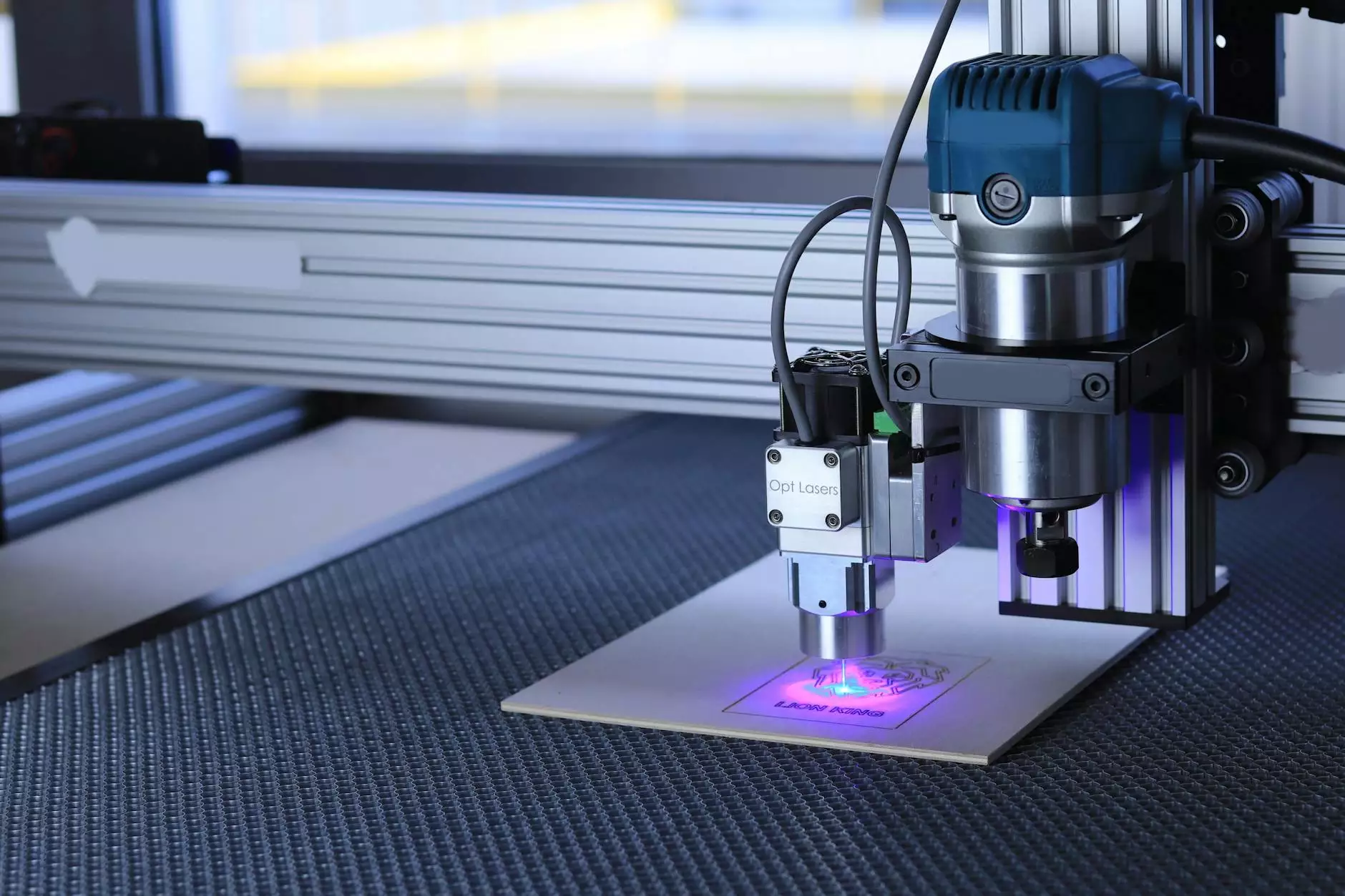

At Quick Parts, we understand the incredible potential of laser metal 3D printing and its impact on businesses worldwide. This innovative technology allows for the creation of complex and customized parts with exceptional precision, speed, and efficiency.

Benefits of Laser Metal 3D Printing

Laser metal 3D printing offers a multitude of benefits for businesses:

- Design Freedom: With laser metal 3D printers, businesses can push the boundaries of traditional manufacturing and create intricate designs that were once unimaginable.

- Cost Efficiency: By eliminating the need for expensive tooling and reducing material waste, laser metal 3D printing helps businesses save significantly on production costs.

- Rapid Prototyping: With laser metal 3D printing, businesses can bring their concepts to life in a matter of hours or days, enabling faster product development cycles.

- Reduced Lead Times: Laser metal 3D printing allows for on-demand manufacturing, reducing the typical lead times associated with traditional manufacturing methods.

- Enhanced Performance: Laser metal 3D printing enables the production of parts with improved mechanical properties, such as increased strength and reduced weight.

- Customization: Businesses can easily tailor designs to meet specific customer requirements, offering a higher level of personalization and customer satisfaction.

Applications of Laser Metal 3D Printing

Laser metal 3D printing finds applications in various industries, including:

- Aerospace: Laser metal 3D printing allows for the production of lightweight, high-performance components used in aircraft engines, structural parts, and advanced prototypes.

- Automotive: The automotive industry benefits from laser metal 3D printing by creating complex parts, optimizing vehicle weight, and improving fuel efficiency.

- Medical: Laser metal 3D printing caters to the medical field by fabricating custom implants, prosthetics, and surgical instruments with highly intricate geometries.

- Energy: From turbine parts to heat exchangers, laser metal 3D printing contributes to enhancing energy efficiency and reducing environmental impact.

- Tooling: Laser metal 3D printing offers cost-effective solutions for creating durable, high-precision molds and tooling components.

Advancements in Laser Metal 3D Printing Technology

As experts in the field, Quick Parts stays at the forefront of laser metal 3D printing advancements. We continuously invest in cutting-edge equipment, materials, and software to provide our clients with unmatched solutions.

Materials for Laser Metal 3D Printing

Quick Parts offers a wide range of materials suitable for laser metal 3D printing:

- Titanium: Known for its excellent strength-to-weight ratio and biocompatibility, titanium is widely used in aerospace, medical, and automotive industries.

- Stainless Steel: Stainless steel provides durability, corrosion resistance, and versatility, making it ideal for various applications.

- Aluminum: Lightweight and highly conductive, aluminum is commonly used in automotive, aerospace, and consumer electronics industries.

- Inconel: With its exceptional heat resistance and mechanical properties, Inconel is suitable for demanding applications, including aerospace and energy sectors.

- Cobalt Chromium: This material offers excellent wear resistance and biocompatibility, making it popular in medical and dental applications.

The Future of Laser Metal 3D Printing

The future holds exciting possibilities for laser metal 3D printing. Some of the potential advancements include:

- Multi-Material Printing: Developing the ability to print multiple materials simultaneously would unlock new design opportunities and enhance part functionality.

- Increased Speed and Scale: Ongoing advancements aim to improve print speeds while maintaining high resolution, enabling faster production of complex parts.

- Material Innovations: Researchers are continually exploring and developing new materials with enhanced properties, expanding the range of available options for laser metal 3D printing.

- Integration of Artificial Intelligence: By combining AI and machine learning, laser metal 3D printers could optimize printing processes, predict failures, and minimize material waste.

Conclusion

Quick Parts is committed to delivering top-notch laser metal 3D printing solutions to empower businesses across industries. With our expertise, advanced technology, and comprehensive material options, we stand ready to assist you in realizing your most ambitious projects with unmatched precision and efficiency.

Experience the diverse benefits of laser metal 3D printing by partnering with Quick Parts today. Contact us to discuss your specific requirements and witness the transformative capabilities of this groundbreaking technology firsthand.