Investment Casting Machine - Revolutionizing the 3D Printing Industry

Introduction

In the rapidly evolving world of 3D printing, businesses are constantly seeking innovative solutions to push the boundaries of what can be achieved. One technology that has been gaining significant traction is investment casting machines. At QuickParts.com, we are dedicated to providing cutting-edge equipment and services to help businesses revolutionize their 3D printing capabilities.

What is Investment Casting?

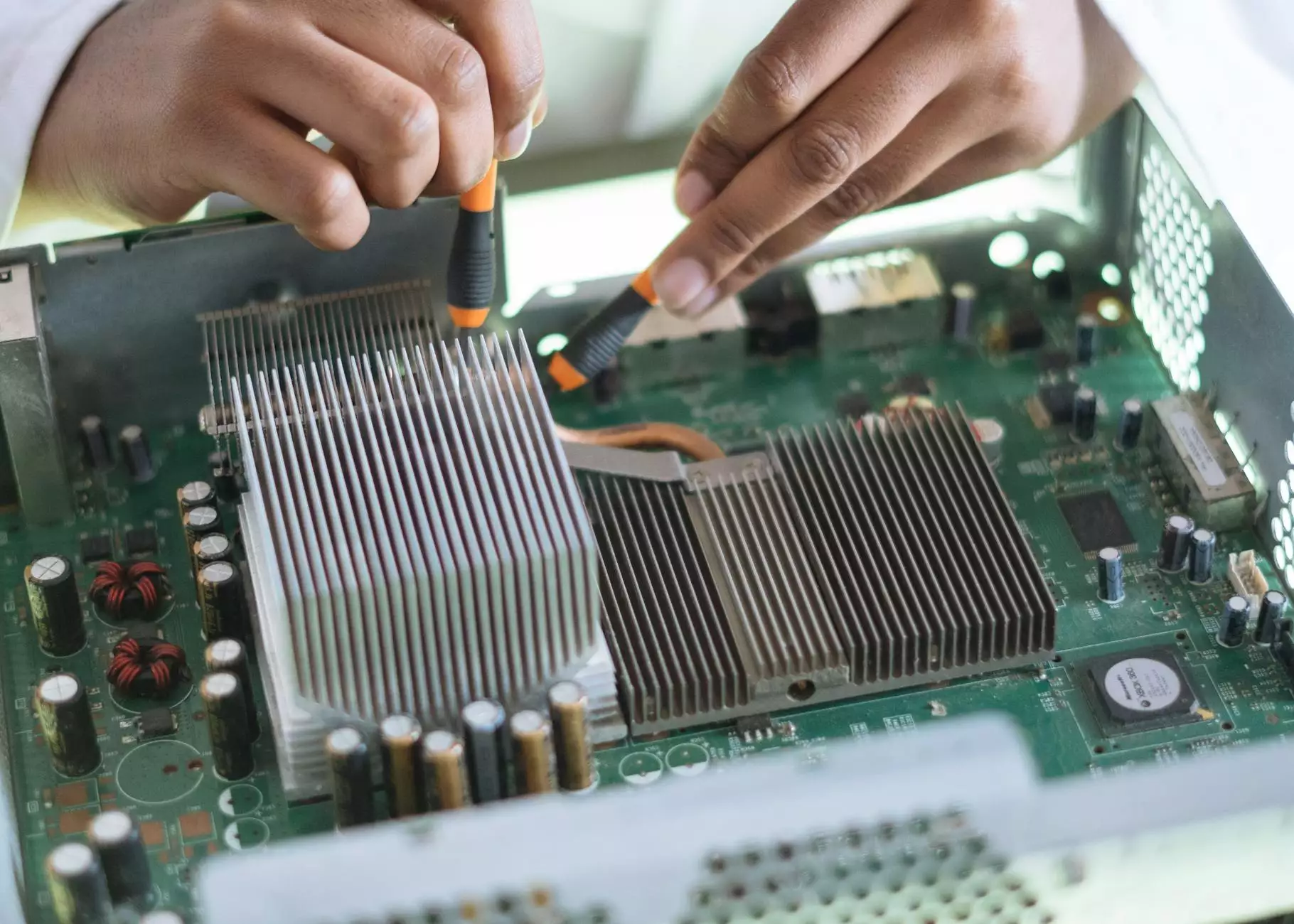

Investment casting, also known as lost-wax casting, is an ancient technique that has been modernized with the advent of 3D printing. It offers unparalleled precision and intricacy, making it a go-to method for manufacturing complex and delicate parts.

The Benefits of Investment Casting Machines

Investment casting machines are a game-changer for businesses in the 3D printing industry. Let's explore the numerous advantages they bring:

1. Enhanced Precision

The investment casting process allows for the creation of intricate designs that traditional manufacturing methods struggle to achieve. By using advanced 3D printing technologies, investment casting machines produce highly detailed parts with tight tolerances, ensuring consistent quality and accuracy.

2. Increased Efficiency

Investment casting machines significantly speed up the production process compared to traditional methods. By utilizing 3D printing technology, businesses can reduce lead times from weeks to days, enabling them to meet tight deadlines and satisfy customer demands promptly. This enhanced efficiency results in cost savings and improved customer satisfaction.

3. Versatility in Material Selection

Investment casting machines offer a wide range of compatible materials, catering to various industries and applications. From metals like stainless steel, aluminum, and titanium to complex ceramics and polymers, the versatility of investment casting machines allows businesses to explore new possibilities and meet the diverse needs of their customers.

4. Reduction in Material Waste

One of the most significant advantages of investment casting machines is their ability to minimize material waste. Traditional manufacturing methods often result in excessive waste due to the subtractive nature of shaping parts. Investment casting machines optimize material usage, leading to significant cost savings and environmentally friendly manufacturing practices.

Applications of Investment Casting Machines in 3D Printing

The applications of investment casting machines are vast and encompass a wide range of industries. Here are a few notable examples:

1. Aerospace and Defense

The aerospace and defense industries require parts with intricate geometries, high strength, and lightweight properties. Investment casting machines excel in producing these components, making them vital in manufacturing critical aircraft and defense system parts.

2. Medical and Dental

Investment casting machines enable the production of complex medical and dental implants with unparalleled precision. From intricately designed dental crowns to customized prosthetic limbs, investment casting offers a transformative solution for the healthcare sector.

3. Automotive

Automobile manufacturers rely on investment casting machines to produce precision parts used in engine components, transmission systems, and even delicate interior features. The ability to create lightweight parts with intricate designs boosts overall vehicle performance and fuel efficiency.

4. Jewelry and Luxury Goods

Investment casting machines have long been a staple in the jewelry and luxury goods industry. The ability to create complex and finely detailed pieces with precious metals and gemstones is unmatched. High-end brands and artisans can now push boundaries and delight their customers with breathtaking designs.

Choosing the Right Investment Casting Machine

Investing in the right investment casting machine is crucial to ensure success in the 3D printing industry. At QuickParts.com, we offer a wide selection of top-of-the-line machines to meet your specific requirements. Our expert team can guide you through the selection process, considering factors such as output volume, material compatibility, and budget constraints.

Furthermore, our after-sales support and maintenance services ensure that your investment casting machine continues to perform optimally, prolonging its lifespan and maximizing your return on investment.

Conclusion

The advent of investment casting machines has revolutionized the 3D printing industry, providing endless possibilities for businesses to create complex and high-quality parts. QuickParts.com is committed to empowering businesses with cutting-edge technology and outstanding support to ensure their success in this ever-evolving field.

Invest in an investment casting machine from QuickParts.com today and unlock your business's true potential in the world of 3D printing.