Why Finite Element Analysis Services

Design & Build Services

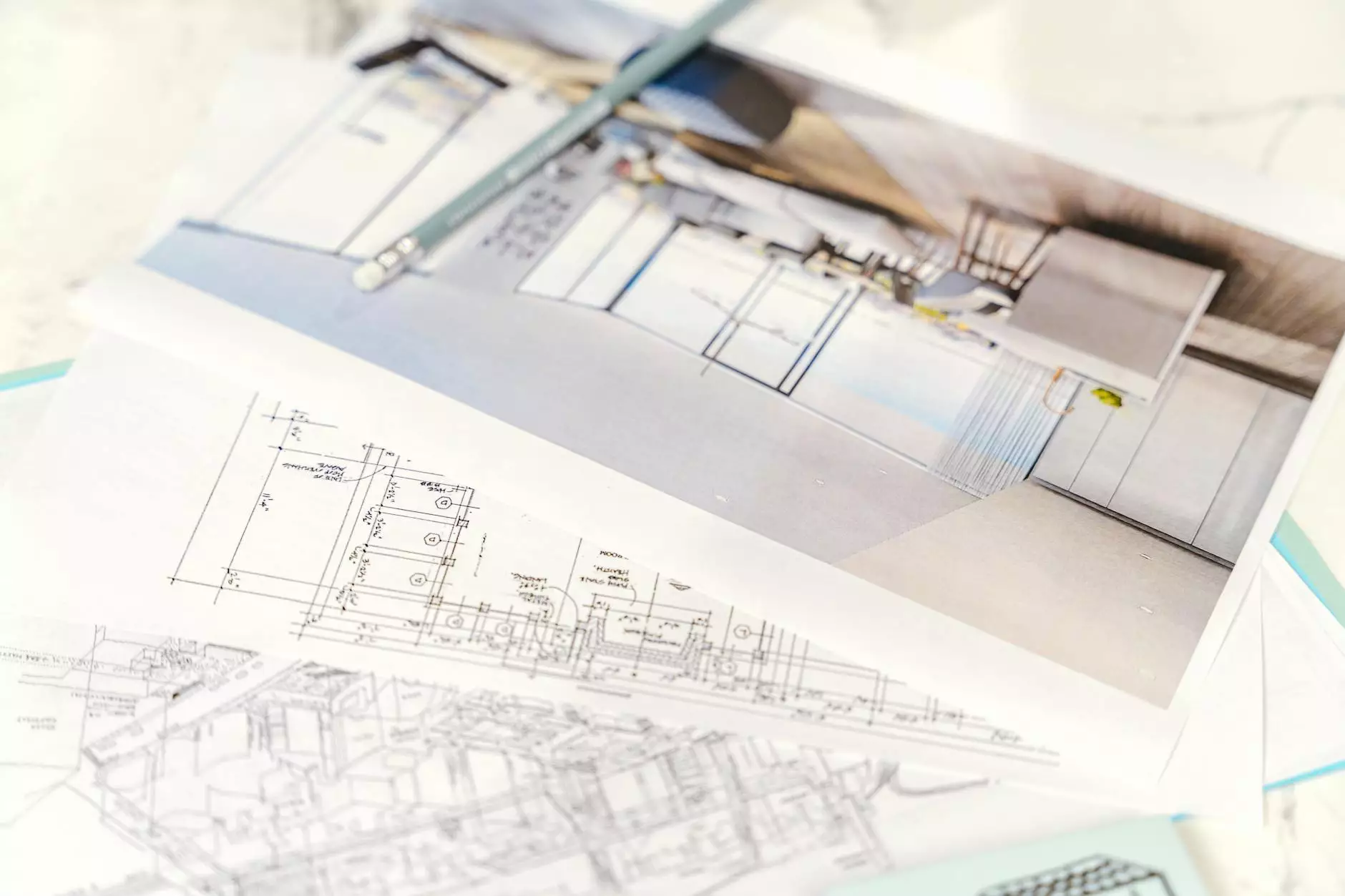

Introduction

Welcome to RPM Design and Prototype, a leading provider of high-quality design and prototyping solutions for various industries. In this article, we will explore why Finite Element Analysis (FEA) has become the most trending thing now and how our company can assist you in optimizing your product's performance through our comprehensive FEA services.

What is Finite Element Analysis?

Finite Element Analysis (FEA) is a powerful numerical method used to analyze complex structures and simulate their behavior under various conditions. By dividing the structure into small finite elements, FEA allows engineers to analyze the stress, strain, and deformation of the product and improve its performance before physical testing.

The Benefits of Finite Element Analysis

Utilizing FEA can provide numerous advantages for product design and development. Some of the key benefits include:

- Improved Product Performance: FEA enables engineers to identify potential design flaws, optimize structural integrity, and enhance the overall performance of the product.

- Cost and Time Savings: By identifying and resolving design issues virtually, FEA allows for significant cost and time savings by reducing the need for physical prototypes and extensive testing.

- Enhanced Safety: Through FEA, engineers can evaluate the safety and reliability of a product, ensuring that it meets industry standards and regulations.

- Design Optimization: FEA provides detailed insights into the performance of different design iterations, enabling engineers to optimize the product's design for maximum efficiency.

- Failure Prediction: FEA allows for the identification of potential failure points, helping engineers implement design changes and prevent costly failures in real-world scenarios.

Key Industries Benefiting from FEA

FEA has found applications in various industries due to its versatile nature. Some of the key industries benefiting from FEA services include:

- Aerospace and Aviation

- Automotive

- Consumer Goods

- Medical Devices

- Manufacturing

- Oil and Gas

- Structural Engineering

- And many more...

Why Choose RPM Design and Prototype for FEA Services?

At RPM Design and Prototype, we specialize in providing comprehensive FEA services tailored to your specific needs. Here's why you should entrust us with your FEA requirements:

Expert Team of Engineers

Our team consists of highly skilled and experienced engineers who are well-versed in the latest FEA techniques and industry best practices. They possess a deep understanding of various materials, structural dynamics, and engineering principles to deliver accurate analysis and reliable results.

State-of-the-Art Technology

We leverage advanced software tools and cutting-edge technology to perform FEA simulations with precision and efficiency. Our extensive hardware resources ensure fast turnaround times while maintaining the highest level of accuracy in our analysis.

Comprehensive Analysis

Our FEA services encompass a wide range of analyses, including structural analysis, thermal analysis, vibration analysis, fatigue analysis, and more. We leave no stone unturned when it comes to evaluating the performance and reliability of your product.

Customized Solutions

We understand that each project is unique, and therefore, we offer personalized solutions to meet your specific requirements. Our engineers work closely with you to understand your goals, constraints, and design objectives, leading to tailored FEA analyses and actionable recommendations.

Collaborative Partnership

We believe in forging strong and collaborative partnerships with our clients. Throughout the FEA process, we maintain open lines of communication, ensuring that you are regularly updated on the progress and results of the analysis. Your feedback and inputs are crucial to us, and we value your active involvement in the project.

Take Your Product Design to the Next Level with RPM Design and Prototype

In conclusion, Finite Element Analysis (FEA) plays a vital role in optimizing product performance and reducing the risk of failure. By employing our industry-leading FEA services at RPM Design and Prototype, you can take your product design to the next level and gain a competitive edge in your market. Contact us today to discuss your FEA requirements and unlock the full potential of your product.