CNC Machining in China: Transforming the Future of Metal Fabrication

In today's global marketplace, efficiency and precision are paramount, particularly in the metal fabrication industry. One of the breakthroughs enabling businesses to achieve these goals is cnc machining china. This technology, characterized by its ability to produce intricate designs with unmatched accuracy, has revolutionized manufacturing processes worldwide.

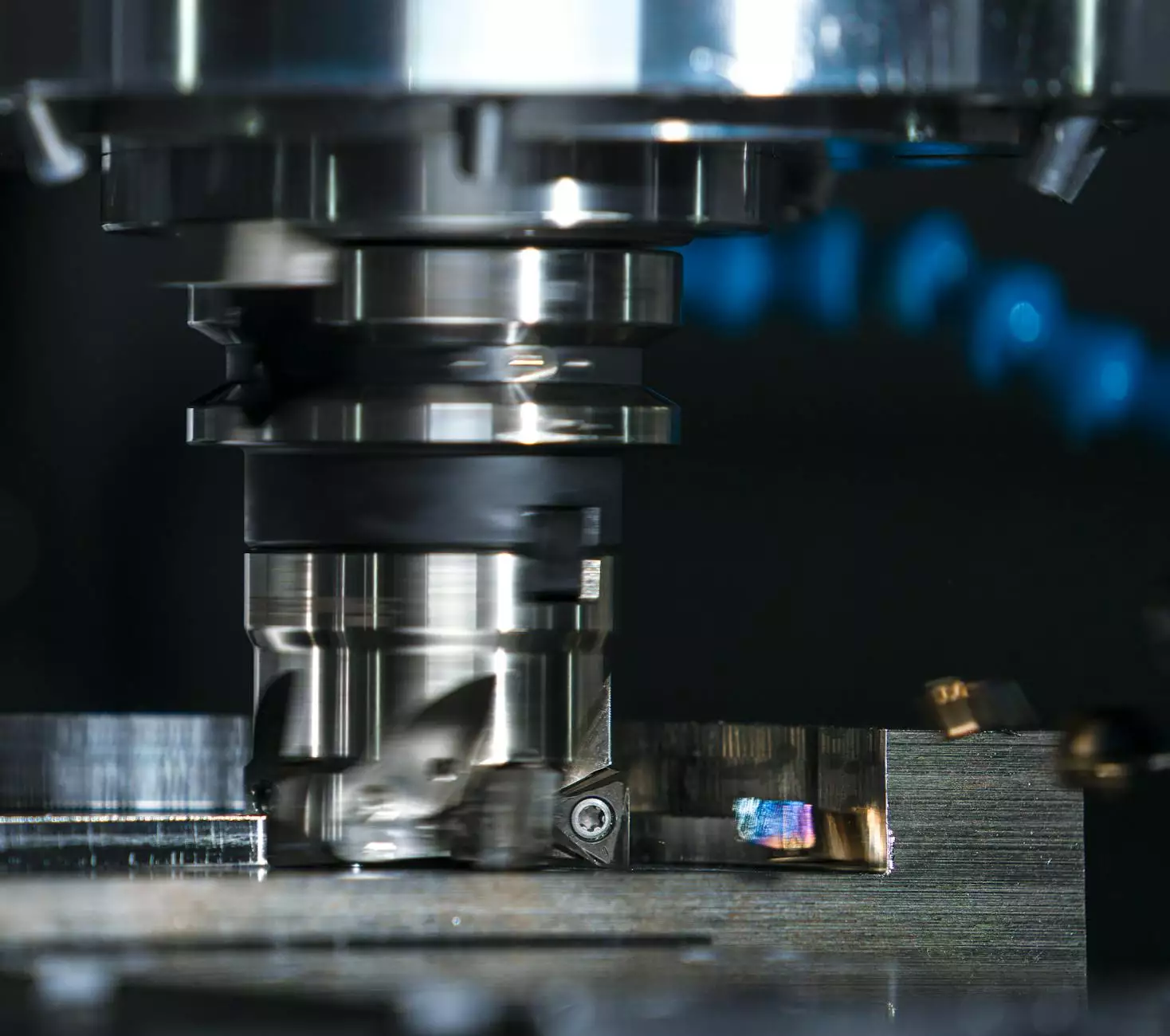

The Fundamentals of CNC Machining

CNC, or Computer Numerical Control, machining refers to the automated control of machining tools using a computer. This method allows for high-speed production with minimal human intervention. The precise programming of machines can produce parts and components ranging from simple geometries to complex designs, all while maintaining a high level of quality.

- Flexibility: CNC machines can work with a variety of materials, including metals, plastics, and composites.

- Precision: Achieves tolerances typically within ±0.005 inches.

- Scalability: Capable of producing small batches to large quantities without loss of quality.

Why Choose CNC Machining in China?

China has established itself as a powerhouse in global manufacturing. When it comes to cnc machining china, here are several compelling reasons to consider this option for your business:

1. Cost-Effective Solutions

One of the most significant advantages of sourcing CNC machining from China is the cost savings. The lower labor costs and the availability of advanced technology enable manufacturers to offer competitive pricing. By choosing Chinese CNC machining services, businesses can:

- Reduce production costs without compromising quality.

- Access high-grade materials at a fraction of the price.

- Maximize profit margins through affordable production capabilities.

2. Advanced Technology and Quality Control

China is not just about low prices; it is equally focused on maintaining high standards in manufacturing. Many CNC machining facilities employ state-of-the-art technology ensuring that every piece meets stringent quality control measures. Benefits include:

- Utilization of latest software for precision programming.

- Implementation of strict quality assurance processes.

- Access to numerous certifications such as ISO, ensuring reliability.

3. Comprehensive Services

For businesses seeking complete solutions, cnc machining china often provides a breadth of services that cover every aspect of the manufacturing process. This can include:

- Custom machining according to client specifications.

- Rapid prototyping services to optimize design and manufacturing processes.

- Post-processing treatments like anodizing, plating, and assembly.

Industries Benefiting from CNC Machining in China

Metal fabricators in China cater to a wide range of industries, providing specialized solutions to meet diverse needs. Some of the key sectors include:

Aerospace and Defense

The aerospace industry demands components that are not only durable but also lightweight. CNC machining in China delivers high-precision components for aircraft and defense systems, contributing to safety and performance.

Automotive

The automotive sector relies heavily on CNC machining for manufacturing intricate parts. From engine components to custom brackets, the ability to produce both traditional and electric vehicle parts efficiently is crucial.

Electronics

In the fast-paced world of electronics, precision is key. CNC machining facilitates the production of complex enclosures, circuit boards, and other critical components, ensuring functionality and reliability.

Working with CNC Machining Vendors in China

To take full advantage of the benefits of CNC machining in China, it is essential to choose the right vendor. Here are key factors to consider:

1. Experience and Reputation

Look for vendors with a proven track record in CNC machining. An experienced supplier will understand the nuances of the industry and possess the technical know-how to deliver high-quality products consistently.

2. Communication Skills

Effective communication is vital for a successful partnership. Ensure that the vendor has excellent communication skills, ideally with English-speaking representatives who can facilitate smooth exchanges of ideas and feedback.

3. Capacity and Scalability

Select a vendor who can handle your volume needs, whether you require small or large-scale production. Their ability to scale operations can significantly impact your project timeline and costs.

4. Technology and Equipment

Investigate the machinery and technology used by the vendor. Facilities that invest in state-of-the-art CNC machines and utilize advanced software are more likely to produce superior results.

Quality Assurance in CNC Machining

To ensure that parts meet desired specifications, quality assurance must be integrated at every stage of the CNC machining process. This can include:

- In-process inspections to verify machine settings and tool conditions.

- Final inspections using coordinate measuring machines (CMM) for dimensional accuracy.

- Testing for material integrity and surface finish checks.

The Future of CNC Machining in China

The landscape of manufacturing continues to evolve, and CNC machining in China is at the forefront of this transformation. As industries push for greater automation, the integration of smart manufacturing technologies and AI will redefine the operational efficiencies. Here’s how the future looks for CNC machining in China:

1. Smart Manufacturing Integration

China’s manufacturing sector is rapidly adopting smart technologies. The integration of IoT (Internet of Things) in CNC machining will enhance data collection, allowing for real-time monitoring and improved decision-making processes.

2. Sustainable Practices

With increasing emphasis on sustainability, CNC machining companies in China are adopting practices that minimize waste and energy use. Sustainable sourcing, energy-efficient machinery, and waste recycling programs are becoming standard practices.

3. Customized Solutions

The trend towards customization continues to rise. Customers now expect more tailored solutions, and CNC machining capabilities in China are evolving to meet these demands effectively.

Conclusion: The Crucial Role of CNC Machining in Metal Fabrication

In conclusion, the advantages of cnc machining china are clear. The combination of cost-effectiveness, advanced technology, and comprehensive services positions China as a leading contender in global manufacturing. For businesses in the metal fabrication industry, embracing CNC machining from reputable Chinese vendors can lead to substantial improvements in productivity and output quality.

As industries evolve, the need for precision machining will only grow. By partnering with the right CNC machining suppliers in China, businesses can stay ahead of the curve, ensuring their products meet the demands of an ever-changing market.

To explore your options in CNC machining and to achieve exceptional results for your projects, visit deepmould.net, where top-quality meets affordable pricing in the world of metal fabrication.