Overview & Advantages of Finite Element Analysis

Design & Build Services

Welcome to RPM Design and Prototype, your trusted partner in innovative product design and development. In this page, we will provide you with a comprehensive overview of Finite Element Analysis (FEA) and its numerous advantages for your design and manufacturing process. Our team of highly skilled engineers and designers are dedicated to optimizing your product's performance through advanced simulations and analysis.

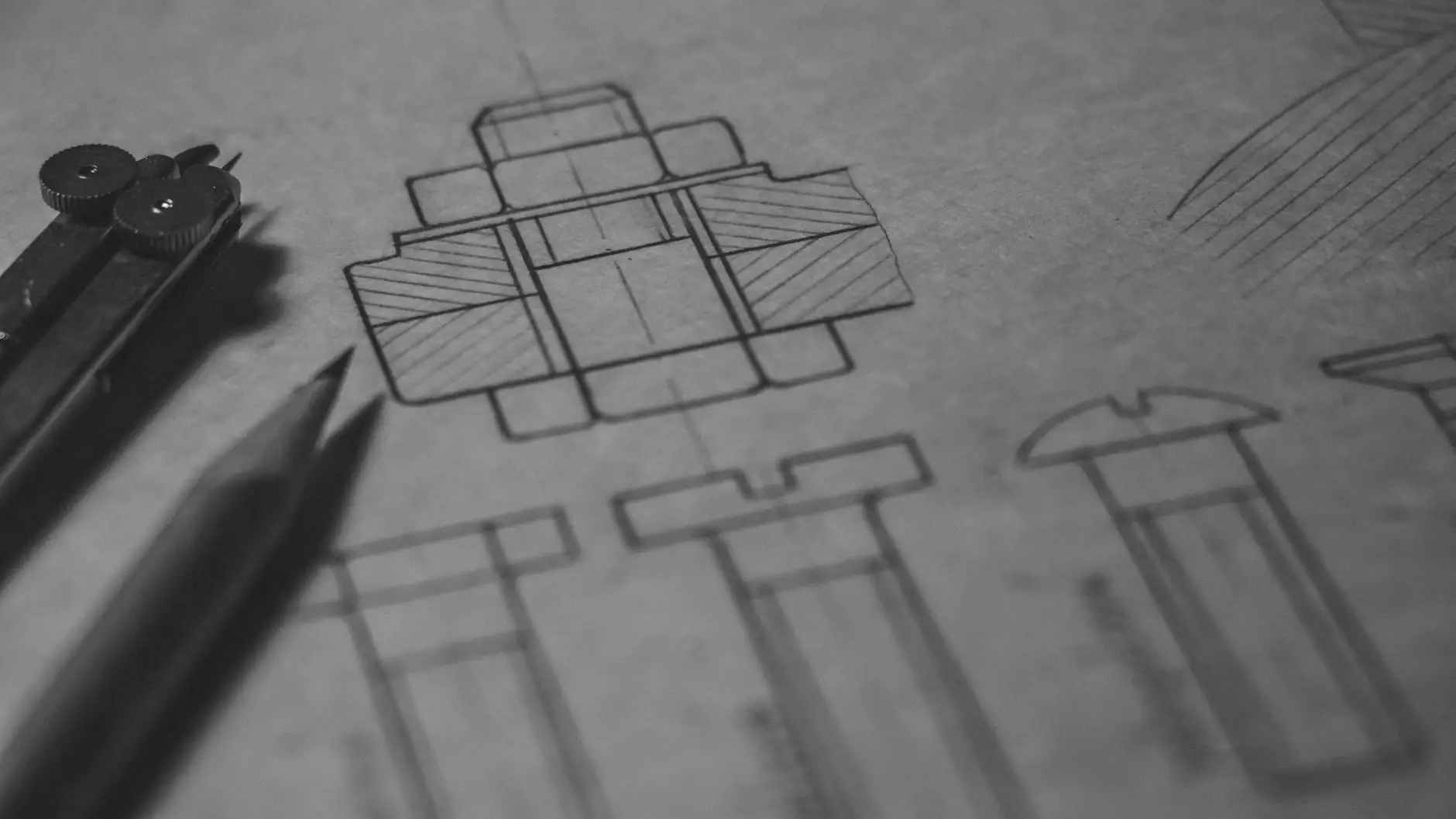

What is Finite Element Analysis?

Finite Element Analysis (FEA) is a powerful engineering technique used to simulate and analyze the behavior of complex structures and systems. By dividing the design into smaller, finite elements, FEA enables accurate predictions of structural behavior under various loads and conditions.

Advantages of Finite Element Analysis

1. Improved Design Optimization

FEA allows engineers to iterate and optimize designs quickly, reducing costly physical prototypes and testing. By running simulations based on real-world conditions, FEA identifies potential design flaws and provides insights for enhancements, resulting in improved performance and functionality.

2. Time and Cost Savings

By utilizing FEA early in the design process, you can identify potential issues and make necessary modifications before manufacturing. This not only saves time but also reduces material waste and overall costs associated with physical prototyping and rework.

3. Predictive Analysis

With FEA, you can accurately predict the behavior and performance of your product under different conditions, such as loads, temperatures, and environmental factors. This helps in making informed decisions and ensuring product reliability and safety.

4. Increased Productivity

FEA enables engineers to simulate and evaluate multiple design variations and scenarios, allowing for faster innovation and faster time-to-market. By analyzing the effects of different materials, geometries, and manufacturing processes, you can optimize your product's performance while meeting project deadlines.

5. Risk Mitigation

By conducting virtual tests through FEA, you can identify potential failure points before investing in physical prototypes or production. This helps mitigate risks and ensures that your product meets industry standards and regulatory requirements.

6. Customization and Adaptability

FEA provides the flexibility to simulate and analyze a wide range of designs and structures, allowing for customization and adaptability. Whether you're developing products in the aerospace, automotive, or consumer goods industry, FEA can cater to your specific needs and design constraints.

7. Better Understanding of Product Behavior

FEA provides engineers and designers with a deep understanding of how their product will behave in real-world scenarios. Through detailed analysis, you can optimize structural integrity, minimize weight, and improve energy efficiency, ultimately creating a superior end product.

Trust RPM Design and Prototype for Your FEA Needs

At RPM Design and Prototype, we have extensive experience in leveraging FEA to enhance product designs and optimize manufacturing processes. Our team of experts will work closely with you to understand your unique requirements and deliver simulations that drive innovation, efficiency, and reliability.

With our state-of-the-art simulation software and advanced analysis techniques, we can accurately predict how your product will perform under real-world conditions, enabling you to make informed decisions and stay ahead of the competition. Contact us today to learn more about our FEA services and how we can help you bring your ideas to life.